What is a Miter Saw Used For?

If you need to cut a variety of angles or repetitive cuts then a miter saw is perfect for you. A miter saw has a blade mounted on a swing arm that pivots left or right to produce angled cuts.

Cuts can be quickly made for crown molding, picture frames, door frames, window casings and more. A miter saw is one of the basic tools that any woodworker should use since it can cut boards quickly and easily. It easy to make repeatable cuts with a miter saw by simply putting a stop at the end of your work surface.

There are three types of miter saws:

- Compound miter saw: blades pivot left and right for angled cuts and tilt in a single direction for beveled cuts.

- Dual compound miter saw: can tilt both left and right plus quickly create bevels at any angle

- Sliding compound miter saw: have a sliding feature allowing the blade to be moved forward and backward. Can cut increased lengths.

Basic cuts with a miter saw:

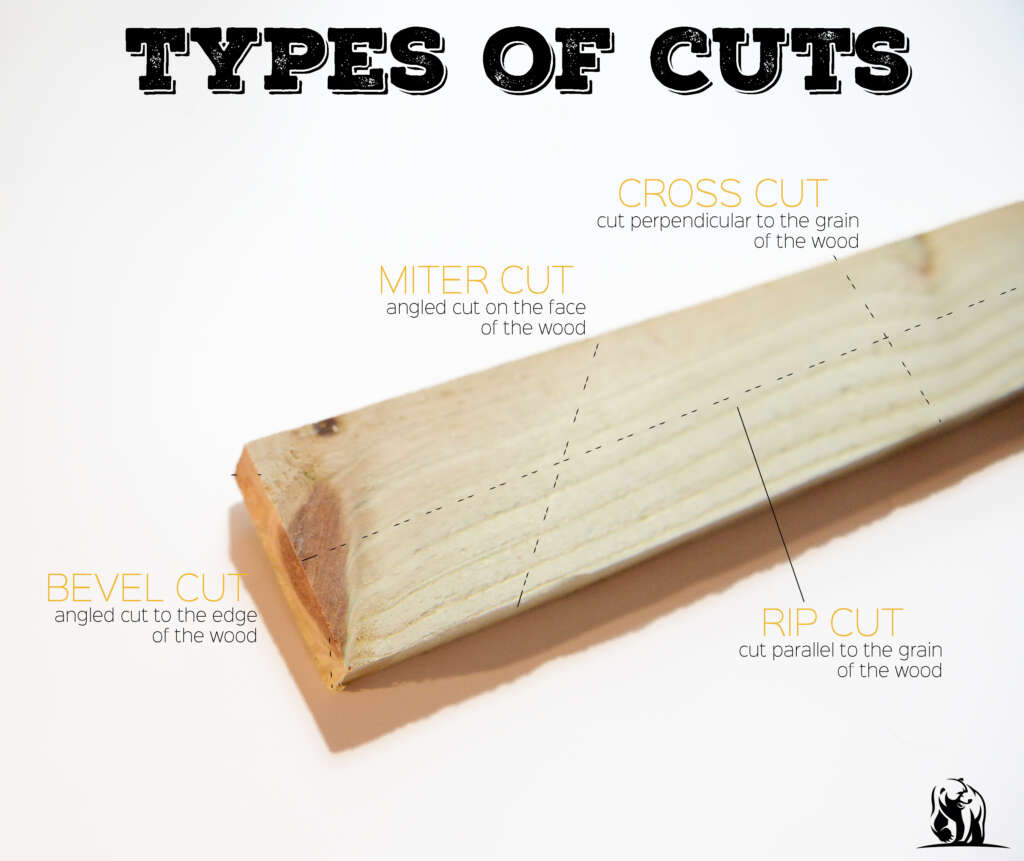

- Regular crosscuts

- A miter saw is a good choice for making regular cuts because it is relatively heavy so you don’t have to worry about it moving while you’re cutting. It is also very easy to line up the cut, you can set a board against the fence and move the handle down to see where the blade will cut. With a sliding miter saw wide boards can be cut, up to 12 inches wide.

- Angled cuts or “miter cuts”

- A miter cut is an angled cut made across the width of the board. Angled cuts are made when the saw is turned to one side or the other, which is necessary in any woodworking project which has angles. Miter cuts are very common in woodworking projects, trim work, flooring and many other DIY projects.

- Beveled and Compound Angle Cuts

- A beveled cut is an angled cut made through the thickness of the board. A bevel plus compound angle cut is made by moving the saw to the left or right and then angling the path of the saw cut. This cut may not be made very often but the miter saw is the best saw for doing so.

Tips for Success

- Cut the factory end from a board before starting a project, the factory edge is not always square

- Don’t force the blade through the wood, let the saw do the work

- More teeth equals smoother cuts. Construction cuts = 50+ teeth. Fine cuts = 90+ teeth.

Miter Saw Safety Tips:

- Unplug the saw when you’re changing the blade or it is not in use

- Keep your fingers at least six inches away from the path of the blade

- Wear safety glasses and hearing protection when operating

- Don’t reach under the blade while it is spinning

- Let the blade come to a complete stop at the end of each cut before lifting it

- Never clamp both sides of the board being cut

Always follow the device manufacturer’s operating, maintenance and safety instructions.